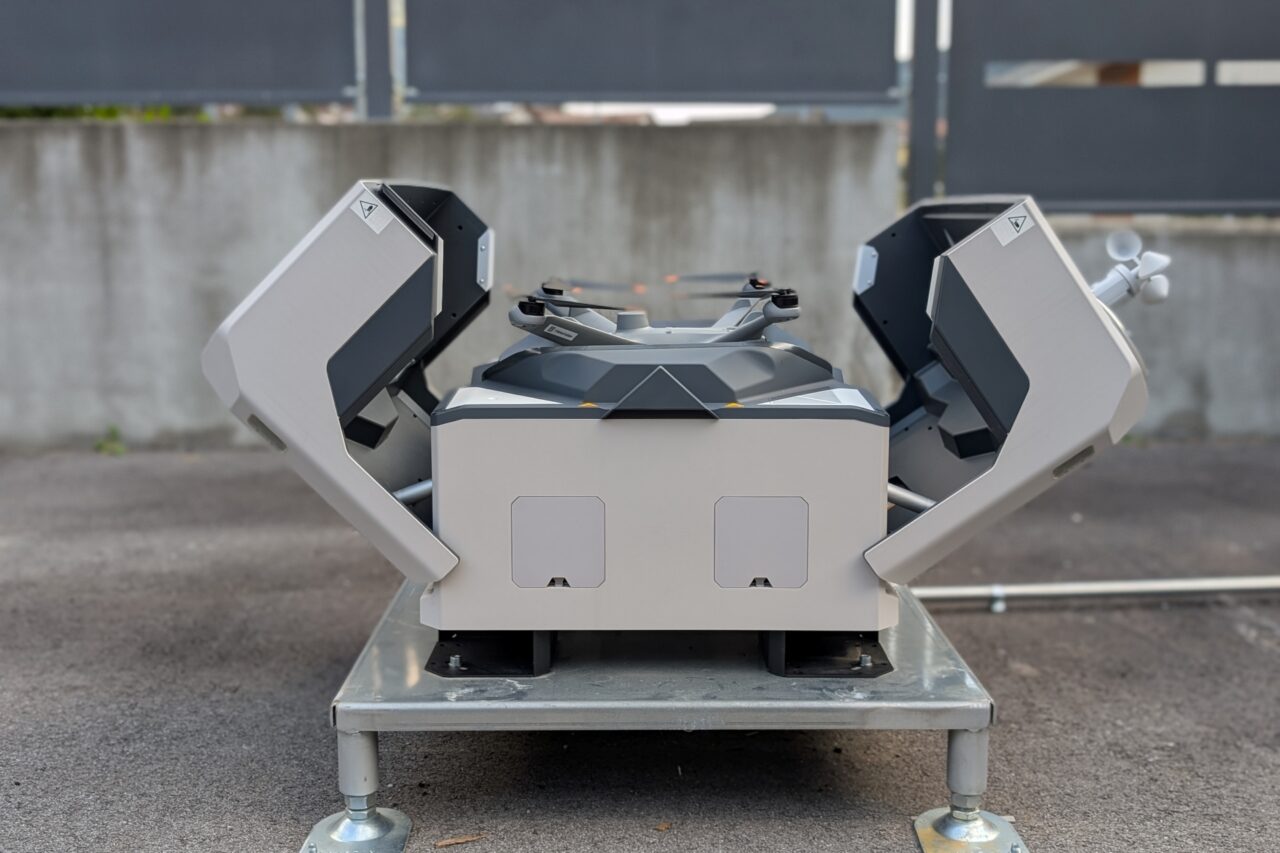

Autonomous drone docking stations are a cutting-edge technology for automating aerial operations. These systems, known as “drone-in-a-box”, integrate take-off, landing, recharging or automatic battery replacement functions into a single infrastructure, allowing the aircraft to perform consecutive missions without the need for an on-site pilot. The goal is making drones truly available on demand, reducing dependence on on-site pilots and enabling scheduled or on-demand missions at any

time.

These systems are used in various sectors. In the monitoring of critical infrastructure, such as power lines, solar farms and bridges, they enable frequent and accurate inspections. In the field of security and surveillance, they ensure continuous monitoring of sensitive areas such as ports, borders and industrial sites.

Features and Technologies

An autonomous docking station is not just a landing platform. It integrates highprecision positioning systems, based on RTK (Real Time Kinematic) or computer vision, which guide the drone during the return phases. The structure is designed to withstand adverse environmental conditions, with IP55 or higher protection ratings, and is equipped with internal climate control to keep the batteries within the optimal temperature range.

Recharging can take place through direct contacts, wirelessly, or via battery swapping systems, which automatically replace the battery pack, reducing downtime to a few minutes. Remote connection ensures mission control and data transfer, allowing the remote pilot to supervise operations and store information directly in the cloud.

Main manufacturers and features

Among the leading international manufacturers are DJI (China) and Hextronics (USA).

- The DJI Dock system, developed in three successive versions, is compatible with the Matrice 30, Matrice 3D and Matrice 4D drones respectively. It guarantees an operating range of approximately 10 km, IP55 protection and resistance to temperatures between -35 °C and +50 °C. Fast charging allows the battery to be recharged from 10% to 90% in approximately 25 minutes, while mission planning and management is carried out remotely via the DJI FlightHub 2 cloud platform.

- Dock systems manufactured by Hextronics, such as Atlas and Universal, feature an automatic battery replacement system that reduces downtime to less than three minutes. The structure, built to withstand harsh environmental conditions, also supports extended missions in remote areas and ensures compatibility with various commercial drone models, from the larger DJI M300 to the more agile DJI Mavic 3 or Parrot Anafi ukr models.

European regulatory framework for BVLOS operations

In Europe, autonomous drone operations in BVLOS (Beyond Visual Line of Sight) mode fall under the Specific Category defined by EASA, the European Union Aviation Safety Agency. To obtain the necessary authorisation, a risk assessment must be submitted to the national aviation authority, conducted according to the SORA (Specific Operations Risk Assessment) methodology.

Standard scenarios (STS) and predefined risk assessments (PDRA) are available to simplify the authorisation process, but the use of autonomous docking stations almost always requires a dedicated analysis, particularly for operations in uncontrolled spaces or with long-duration flights.

Conclusion

Autonomous docking stations represent a strategic infrastructure for the evolution of drone operations, ensuring levels of automation and reliability that were unattainable until recently. Market leaders have developed robust, scalable solutions that comply with safety standards, promoting their widespread use in areas of strategic importance.

In the coming years, we can expect to see increasing integration with artificial intelligence systems capable of automatically processing and interpreting the data collected. The adoption of these technologies marks the transition to a new operating paradigm, in which information is acquired in a consistent and accurate way, independent of the physical presence of operators.